Plastic Bottle vs Glass Bottle for Cosmetic Packaging

Introduction

The main bottle container for cosmetics are no more than these two types – “glass bottles” and “plastic bottles” , both of which play a different and important role in cosmetics packaging.

Glass bottles occupy a relatively small portion, while plastic bottles and other alternatives dominate the majority of the market share.

However, there is a special phenomenon in the cosmetic industry, that is,”high-end cosmetic products prefer glass bottle packaging”.

Why do high-end cosmetics prefer glass bottles? What are the reasons behind it?

And why the plastic bottles can account for a big part of the cosmetic packaging market? What are the advantages of plastic bottles?

Just read through this blog, and you will get the answers.

Table of Content:

1.Plastic bottle VS glass bottle for cosmetic packaging

1.1 Advantages and disadvantages of plastic bottle for cosmetic

1.2 Development of plastic bottle for cosmetic(PLA material and its benefits)

1.3 Advantages and disadvantages of glass bottle for cosmetic

2. Reasons for preferring glass bottle for cosmetic packaging

3. How to choose a cosmetic glass bottle manufacturer

1. Plastic bottle VS glass bottle for cosmetic packaging

In fact, both cosmetic plastic bottles and glass bottles are not absolutely good or bad.

Different companies, different brands, and different products, according to their own brand and product positioning, cost, profit target needs, choose to use different cosmetic packaging materials.

Let’s analyze the advantages and disadvantages of cosmetic plastic bottles and glass bottles so that may better help you make a choice.

1.1 Advantages and disadvantages of plastic bottle for cosmetic

Advantages

1) Lightweight and durable:

Cosmetic plastic bottles are lightweight and less prone to breakage, resulting in cost savings on transportation and reduced risk of product damage.

2) Versatile customization:

Cosmetic plastic bottles offer a wide range of customization options, such as labeling, screen printing, spray painting, foil stamping in gold or silver, frosted finishes, and more. These techniques allow for branding and aesthetic enhancements to meet specific requirements. Additionally,cosmetic plastic bottles can be produced with low minimum order quantities, starting as low as 500 units.

3) Recyclability:

Cosmetic plastic bottles are recyclable, contributing to environmental sustainability. By implementing appropriate recycling processes, cosmetic plastic bottles can be reused and transformed into new products, reducing waste and promoting a circular economy.

4) Cost-effective alternative:

When compared to cosmetic glass bottles, cosmetic plastic bottles stand out for their cost-effectiveness. Enjoy the advantage of reduced production costs, translating into competitive pricing for your products without compromising on quality.

Disadvantages

1) Reduced barrier properties:

While advancements have been made in plastic cosmetic bottle technology, glass still offers superior barrier properties against oxygen and other gases. This makes cosmetic glass bottles a better choice for products that are sensitive to air exposure, such as certain beverages or cosmetics.

2) Susceptibility to scratches and wear:

Plastic cosmetic bottles are more prone to scratches and wear over time compared to cosmetic glass bottles. This can affect the overall appearance and aesthetics of the packaging, potentially impacting the brand perception.

3) Significant environmental impact:

Plastic cosmetic bottles contribute significantly to environmental degradation, exacerbating the issue of plastic pollution.

1.2 Development of plastic bottle for cosmetic(PLA material and its benefits)

With the development of technology, new plastic material has been applied in the production of plastic containers for cosmetics.

Polylactic acid, also known as poly(propylene glycol), belongs to the polyester family.It is a new type of biodegradable material made from renewable plant resources (e.g. corn) by fermentation process to make lactic acid, which is then converted to PLA by polymer synthesis.It is well-sourced and renewable.

The production process of PLA is pollution-free, and the product is biodegradable and recyclable in nature, making it an ideal green polymer material.

image from https://www.ecolink-bamboo.com/

Benefits of polylactic acid (PLA)

1) Environmental friendly:

PLA has excellent biodegradability and can be completely degraded by microorganisms in the soil within one year after disposal, generating carbon dioxide and water, without pollution to the environment. “From nature, back to nature”! That’s what Pla can achieve.

The world’s carbon dioxide emissions according to news reports in 2030 the global temperature will rise to 60 ℃, the treatment of ordinary plastic is still burning cremation, resulting in a large number of greenhouse gases into the air, while PLA is buried in the soil to degrade, the carbon dioxide generated directly into the soil organic matter or absorbed by plants, will not be discharged into the air, will not cause the greenhouse effect.

2) Suitable for various processing methods:

The processing methods include such as blow molding, injection molding, etc. It is easy to process and very widely used. It can be used to process various food packaging containers, fast food lunch boxes, non-woven fabrics, and industrial and civil cloths and so on.

In turn, it can be processed into agricultural fabrics, health care fabrics, wipes, sanitary products, outdoor UV protection fabrics, tent fabrics, floor mats, etc.

The market prospect is very promising. It can be seen that its mechanical properties and physical properties are good.

3) Wide applications:

The basic physical properties of polylactic acid (PLA) are similar to those of petrochemical synthetic plastics, which means that they can be used in a wide range of applications.

PLA also has good gloss and transparency, comparable to films made from polystyrene, those other biodegradable products cannot provide.

4) Superior compatibility and degradability:

PLA is also used in a wide range of pharmaceutical applications, such as disposable infusion sets, no-disassembly surgical sutures, and low-molecular PLA as a slow-release packaging agent for drugs.

5) Safety:

polylactic acid (PLA) film has good permeability, oxygen permeability, and permeability to dioxide carbon, it also has the property of isolating odor.

1.3 Advantages and disadvantages of glass bottle for cosmetic

Advantages

1)Luxury and elegance:

Glass cosmetic bottles exude a sense of luxury and elegance. Their transparency allows for product visibility, which can enhance the consumer’s perception of the product’s quality.

2)Stability and non-toxicity:

Glass cosmetic bottles are stable non-toxic and not easy to produce a chemical reaction with skin care products. Their good barrier prevents the cosmetics from deteriorating.

3)Strength and rigidity:

Strong rigidity enables the cosmetic glass bottles not easy to deform, in addition to the heavier weight, cosmetic glass bottles provide the consumers with a better hand feeling.

4)Temperature tolerance:

Glass cosmetic bottles demonstrate excellent temperature tolerance, allowing them to endure high temperatures during sterilization processes and maintain their structural integrity even when stored at low temperatures.

5)Sustainability and recyclability:

Glass is 100% recyclable and can be recycled indefinitely without any loss in quality. Using cosmetic glass bottles reduces the demand for new raw materials and helps decrease the environmental impact.

Disadvantages

1)Brittleness and fragility:

Glass cosmetic bottles are brittle, easy to break, and not easy to store and transport.

Reading this, you might want to learn about the various types of void fill that would help solve this shortcoming.

2)Weight and transportation costs:

The weight of cosmetic glass bottles is large, and the transportation cost is high, especially for e-commerce express.

3)High energy consumption in manufacturing:

The manufacturing of glass is highly energy-consuming. This is due to the high temperature required for processing and manufacturing.

4)Limited custom options:

While cosmetic glass bottles can be molded into various shapes, the customization options are generally more limited compared to cosmetic plastic bottles. Techniques like embossing and debossing are possible but may not be as intricate as with cosmetic plastic bottles.

2. Reasons for preferring glass bottle for cosmetic packaging

1) Ensuring cosmetic efficacy with glass bottles

The pursuit of high functionality, multi-functionality, and quality assurance is essential to enhance the primary function of protecting the contents within packaging.

For high-end cosmetics, particularly in the era of “efficacy skin care,” the preference for glass bottle packaging is becoming increasingly common.

Through analysis, it is evident that glass cosmetic bottles possess characteristics such as stability, excellent barrier properties, heat resistance, light resistance, and solvent resistance. These attributes make glass cosmetic bottles highly suitable for skin care products, as they minimize the likelihood of chemical reactions.

Cosmetic glass bottles are the most reliable option in terms of safety and stability. They are particularly beneficial for preserving cosmetic products with active ingredients like antioxidants, anti-aging agents, and whitening components, which are sensitive to light exposure.

Moreover, glass cosmetic bottles exhibit exceptional gas barrier properties, making them the preferred choice for packaging perfumes and other fragrance products that are volatile and easily dissipate. This explains why glass cosmetic bottles dominate the perfume packaging market.

2) Elevating brands through distinctive glass bottle designs

Cosmetics, in general, often lack a distinctive appearance as they are typically in liquid, milky liquid, or cream form. To express the unique characteristics of these products, they require the design of beautiful and distinctive glass bottles.

In the current market, many cosmetic brands opt for translucent or fully transparent glass cosmetic bottles to showcase the composition and color of the product.

From a consumer perspective, the initial goal is to capture their attention and ignite their desire to purchase. Transparent and pure aesthetics evoke a sense of nobility and elegance, which is the captivating allure of glass cosmetic bottles.

Therefore, cosmetic manufacturers employ fashionable, eye-catching, vibrant, and intriguing glass bottle designs as a means to outshine their competitors.

As the “coat” of the cosmetic products, glass cosmetic bottles serve not only the function of holding and protecting the contents but also play a crucial role in attracting customers and influencing their purchase decisions.

3) Reflecting the cultural value of cosmetics through glass bottles

In the market, various skin care ideas are emerging, and various glass bottles are competing with each other, making people dazzled.

Many products not only tell people how efficient their product is but also sell fashion and culture.

The fashion and culture of cosmetics are usually what we call taste.

How to reflect the taste of cosmetics, in addition to product advertising and product counter display and other aspects, the cosmetic glass bottle is an important link and carrier.

A decent glass cosmetic bottle can not only directly stimulate the senses of consumers, but also can reflect the taste of the product.

In addition, the heaviness of the glass cosmetic bottle can make consumers trust and improve the grade of cosmetics, which is impossible to do with cosmetic plastic bottle packaging.

Cosmetics are “selling dreams, selling fashion, selling hope”, and the psychological value of cosmetics play a big role. Some well-known and up-market skincare brands can sell them at a high price of hundreds of dollars.

4) Glass bottles as a sustainable solution for cosmetic packaging

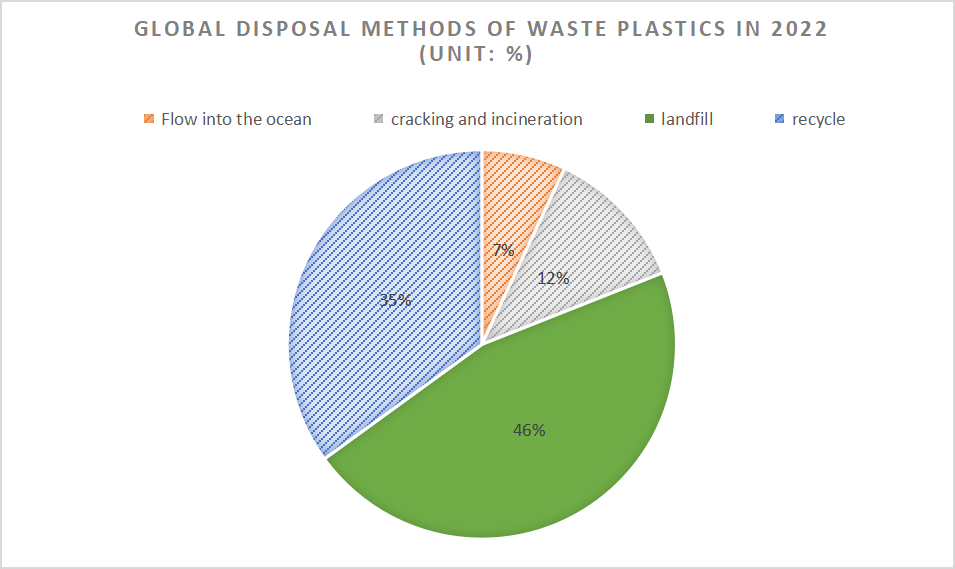

Because of the plastic restriction, packaging which is green, eco-friendly, and reusable has become the first choice of enterprises. Cosmetic packaging is no exception.

Data shows that the discarded plastic bottles from Coca-Cola, Pepsi, and Nestle have become the world’s top three largest plastic polluters.

Forced by the relevant laws and external public opinion pressure, these companies have implemented plastic bottle recycling, the implementation of renewable plastic bottles, and other measures.However, there is still a long distance from totally using biodegradable plastic.

Therefore, glass bottles can be recycled and reused without pollution to the environment, which should also be one of the important reasons why high-end cosmetics prefer glass bottle packaging.

Among them, the recycling of glass bottles attracts consumers to join the environmental protection activities.

On the one hand, they are taking on their own responsibility to directly face the challenges of environmental protection and social responsibility;

on the other hand, they are actively communicating with consumers through these environmental protection activities, which greatly enhances the brand reputation of the company.

Click to learn more info about environmentally friendly packaging.

3. How to choose a cosmetic glass bottle manufacturer?

As analyzed above, “ensuring cosmetic efficacy with glass bottles, elevating brands through distinctive glass bottle designs,reflecting the cultural value of cosmetics through glass bottles,glass bottles as a sustainable solution for cosmetic packaging” are the four main reasons why high-end cosmetic brands prefer to choose glass bottles.

So, for the above four reasons, how to choose an excellent and reliable cosmetic glass bottle manufacturer becomes the key for cosmetic brands.

Choosing a cosmetic glass bottle manufacturer is a test for the brand – because it involves quality, quality, price, efficiency, market competitiveness, corporate profit, and many other aspects.

1) Design & development ability and innovative technology

The appearance, style and quality of a cosmetic glass bottle reflect the design and development capabilities, and innovative technology of cosmetic glass bottle manufacturers.

Therefore, this is the first element in the selection among them.

Especially when you need to make a private mold,many factors should be considered such as design, material selection, cycle time, cost, process details, effects, etc.

2) Price and cost performance

The price and cost performance of cosmetic glass bottles are the powerful weapons that can make the brand stand out in homogenization.

Generally speaking, “inexpensive”cosmetic glass bottles can bring the company a reasonable profit margin and higher competition.

3) Production scale and production efficiency

The cosmetic glass bottle manufacturer’s production qualifications, the number of production lines, production equipment, production quality, and production efficiency, directly determine the product supply quantity and speed and indirectly determine the performance of corporate brand marketing.

Before making a decision, you have to go through the manufacturer from hand to toe.

In this way, it can effectively eliminate or reduce the number of products of substandard quality, delayed delivery or delivery shortage, and other bad conditions.

4) Samples and portfolio

Request samples of the manufacturer’s previous work. This will give you an idea of their capabilities, craftsmanship, and the quality of their products. A manufacturer with a diverse and impressive portfolio is more likely to meet your expectations.

5) Reviews and references

Look for reviews and testimonials from other clients who have worked with the manufacturer. You might also consider reaching out to these clients directly for more insight into their experiences.

Conclusion

So there you have it- the advantages and disadvantages of plastic and glass cosmetic bottles. Hopefully, this article has helped you make a more informed decision about which type of bottle will be best for your product and brand promotion.

If you’re still not sure, or you need help finding a reliable cosmetic glass bottle manufacturer, don’t hesitate to get in touch with us. Here at Primepac, with extensive experience in the packaging industry, we’re dedicated to tailoring solutions to suit your brand’s unique requirements, leaving a memorable impression and building customer loyalty.

We would be happy to assist you in choosing the perfect packaging for your cosmetics products. Thanks for reading!

An Useful Guide to Box for Cosmetic Packaging

Introduction

It is no secret that cosmetic packaging is important to the success of a product.

After all, it is one of the most important factors that will ultimately determine how well the product sells.

This is why many cosmetic companies invest heavily in their packaging, making sure that it is both eye-catching and able to properly showcase the product.

Of course, there is more to cosmetic packaging than just aesthetics.

The packaging must also be functional, ensuring that the product is protected from damage and remains fresh for as long as possible.

Box for cosmetic packaging is the first thing that you should take care about because it can attract customers from all the competitors on the shelf at the first glance. Besides, a high-quality box for cosmetic packaging can protect your products inside well.

In other words, cosmetic packaging must strike the perfect balance between form and function in order to be successful.

So, if you are planning to launch a new cosmetic product, make sure to give its packaging the attention it deserves. Otherwise, you may find that your product does not reach its full potential in the market.

This blog will include the following content:

1. Cosmetic packaging is very important to the success of a product

2. Different types of cosmetic packaging

3. box packaging design

The importance of cosmetic packaging

1. Attract buyers’ eyes

A good cosmetic packaging design can better attract consumers and thus increase the sales of the brand.

We can see in many shopping malls that the cosmetic packaging of any brand is very beautiful and stylish, even if it is the same brand and different series of cosmetics will have a unique design.

One of the roles of cosmetics is to allow users to change their appearance and thus improve their self-confidence, and a well-designed package can make your product more trustworthy.

Once people have consumed all the products, the packaging can be used as a small artifact to keep at home. The packaging will be a lasting advertisement.

2、Reflect the brand quality

The packaging design of cosmetic products can reflect the level of the cosmetic brand.

The packaging design shows that the manufacturer is very attentive to any aspect of cosmetics, even the packaging has taken a lot of effort. The quality of the product inside is certainly guaranteed.

3. Act as a good advertisement

A good cosmetic packaging design should be able to attract the attention of consumers and make them interested in the product, as cosmetics directly affect their appearance.

Therefore, the packaging design of cosmetics should never be too cheap and should not be made of very cheap materials.

Nowadays, consumers are paying more and more attention to the packaging of cosmetics, and a successful cosmetic packaging design is very attractive to the majority of female consumers.

4. Brand perception and product differentiation

If you want your brand to be different from other brands, choose a unique and innovative design for the packaging.

Wholesale cosmetic packaging with its own color scheme and special designs can prove useful in the marketplace.

These factors can make your brand stand out from the rest of the products on the shelf.

Customers will find it attractive when they can easily find the desired product.

Therefore, in order to win the hearts and minds of your customers, you must carefully design the packaging of your cosmetics.

5. Provide the necessary information about the packaging

Cosmetics are applied to the skin, which is why there are different types of cosmetics for different types of skin. It is important to find the right cosmetics for your skin type.

Custom cosmetic boxes solve your problem; these boxes help you find the products you need. Customers will be happy with your brand if the information is clearly printed on your product packaging.

Different types of materials can be used for cosmetic packaging

Cosmetic box packaging materials are divided into the main container and auxiliary materials. The main container usually has plastic bottles, glass bottles, tubes, vacuum bottles, etc. Auxiliary materials are usually: cosmetic packaging box, inner tray,

Plastic bottles

1. Plastic bottles are generally made of PP, PE, ABS, ABS, acrylic, PET, etc.

2. PET material is environmentally friendly, lightweight, unbreakable, and chemically resistant. Transparent. Products made of this material can be made into pearlescent, colorful, magnetic white.

Widely used in the installation of jelly water. Bottle mouth is generally standard 16 #, 18 #, 22 #, and 24 # caliber, and can be used with the pump head.

3. Acrylic material is mostly used for injection molding bottles, chemical resistance is poor, generally can not be directly filled with products, and need to be equipped with a liner compartment.

It should not be completely filled to prevent the cream from entering the middle of the dinner and bottle to avoid cracking.

The requirements for transportation are very high.

4. AS, ABS.

AS has better transparency and toughness than ABS.

5. Australia mold development cost: blow mold $200-600, injection mold $1000-3000 ranging

Stainless steel material molds will be more expensive than alloy material molds, but durable.

How many molds do you need and how many times do the molds come out at a time depends on the production volume,

6. The initial order quantity is usually 3000-10000 pieces, and the color can be customized.

Most people will choose the original color and magnetic white, or add a pearl powder effect, although the bottle and the cap will be the same color, the color of the final product will be different depending on the material used for the bottle and the cap.

Glass bottle

1, Glass bottles for cosmetics are mainly divided into skin care products (creams, lotions), perfumes, essential oils, and nail polish, most of them are in a small capacity, which is less than 200ml.

2, glass bottles are divided into wide-mouth bottles, narrow-mouth bottles, and solid creams are generally used in wide-mouth bottles, it is appropriate to match the electrochemical aluminum cap or plastic lid, the cap can be used for color spray oil and other effects;

An emulsion or aqueous creams are generally used in narrow-mouth bottles, it is appropriate to match with the pump head. We need to pay attention to prevent the spring and ball rust, now most of the pump heads will use glass beads,

3, glass bottles are more consistent in the selection of materials, have more shapes, processing technology is rich, and the cap is diversified,

common bottle shapes are cylindrical, oval, flat, prismatic, conical, etc.,

manufacturers often develop a series of bottle shapes.

4. In Glass bottles such as those made by hand-made mold, there will be a little deviation in the capacity. the product should be tested, and make the correct capacity label

5. Glass bottles of uneven thickness will easily lead to damage, or easy to be squeezed to break by the contents in the cold conditions,

It should be filling at a reasonable capacity,

In the transportation, Single separation should be applied to the glass bottle for protection.

6. Commonly used glass bottles are usually available in stock, such as refined oil bottles, and plain clear, or frosted bottles.

Glass bottle production cycle is long, as soon as 20 days, some delivery period is 45 days, the general order quantity is 5,000 to 10,000, the smaller the bottle type to do more, cycle and mom will be affected by peak season, off-season.

7. bottle cap process can be electrolyzed aluminum lettering, bronzing edge, etching lines, and dumb light color, to match the gasket and inner cover, it is best to use the pressure-sensitive piece to strengthen the sealing effect.

8. Refined oil bottles are usually used in brown or colored and colored frosted, which enables the bottle to avoid light.

The cover has a safety ring, which can be matched with an inner plug or dropper, perfume bottles are generally matched with a delicate spray pump head or plastic cover.

Tube

1, Tube can be divided into single, double, or five layers

Their pressure, permeability, and sense of touch are different

five layers of the tube include an outer layer, an inner layer, two adhesive layers, and another barrier layer.

Features: with excellent gas barrier performance, it can effectively prevent the infiltration of oxygen and odor gas. Besides, it can also prevent the fragrance of the content and the exudation of active ingredients.

2, the double-layer tube is more commonly used.

the middle and low-end products will use the single-layer tube.

the caliber of the hose is various from 13# – to 60#

for the beauty and harmony, 60ml below product commonly use the caliber under 35# product volume like100ml, 150ml usually use the caliber from 35# – 45# caliber, capacity more than 150ml will use the caliber of 45#

3, the shape of the tube includes round, oval, flat, and super flat.

As the latest kinds of tubes, flat tubes, exceed flat-tube are more complex than any other tubes in the production process, so the price is correspondingly more expensive.

4. tube cover also have various shapes, such as flat caps, round caps, high caps, lift caps, super flat caps, double caps, spherical caps, lipstick caps, and plastic caps

Cap can also be processed in a variety of processes, bronzing edge, silver edge, colored caps, transparent, oil spraying, electroplating, etc., tip caps and lipstick caps are usually equipped with inner plugs.

5, some products need to fill after sealing, sealing is divided into straight-line sealing, twill sealing, umbrella sealing, star sealing, and special-shaped sealing, During the sealing process, the manufacturers can print out the required date code

6, Tube production cycle is generally 15 days to 20 days (from the confirmation of the sample tube)

Order quantity per product from 5 thousand to 10 thousand, large manufacturers usually take 10 thousand as the minimum order quantity, few small manufacturers will accept 3 thousand per product if there are many varieties in one order.

Few customers will make a totally brand new mold by themselves,

Most of them are public models (a few featured LIDS are private models). There is a ±10% deviation between the contracted quantity and the actual supply quantity in this industry.

Box

A box for cosmetic packaging is a type of container that is specifically designed to hold and protect cosmetics.

Cosmetic boxes come in a variety of sizes, shapes, and materials, and can be custom-made to fit the needs of any business.

Cosmetic boxes are an important part of the cosmetic packaging process because they help to keep products safe from damage during shipping and storage.

They also provide a way to display products in a retail setting. Boxes for cosmetic packaging can be made from a variety of materials, including cardboard, plastic, metal, or wood.

Cardboard is the most common material used for cosmetic boxes because it is lightweight and easy to work with.

Cardboard boxes can be printed with colorful designs and logos and can be die-cut to any shape.

Plastic cosmetic boxes are also popular because they are durable and offer a clear window for product visibility. Metal and wood boxes are less common, but can provide a more luxurious look for high-end cosmetics.

When selecting a box for cosmetic packaging, it is important to consider the type of product that will be packaged inside.

Boxes for liquid cosmetics, such as foundations and perfumes, need to be leak-proof and have tight-fitting lids.

Boxes for powders, eyeshadows, and blushes should have compartments or trays to keep products from shifting during shipping.

And boxes for lipsticks and other small items need to have individual compartments or slots to keep products organized and easy to find.

Cosmetic boxes can be purchased from a variety of sources, including packaging suppliers, printing companies, and online retailers. They can also be custom-made to specific size and shape requirements.

When selecting a box for cosmetic packaging, it is important to compare prices and turnaround times from multiple vendors to ensure the best possible price and delivery time.

Cosmetic Box Design

Cosmetic product packaging, like any other commodity, is required to achieve the final sale by virtue of packaging and is a commodity that relies heavily on the packaging.

This is not only because the characteristics of cosmetic ingredients dictate the need for reasonable packaging that protects the safety and stability of the product, but also because cosmetics themselves are a special commodity that carries people’s desire to beautify themselves.

This is not only because cosmetics in order to achieve successful design results, we also need a systematic and structured design for cosmetic box packaging.

Brand positioning expression

Brand positioning means establishing one’s market position or consumers’ psychological position in response to the target market demand, in such doing, the brand can determine a distinctive proposition for the brand, which should have great appeal to the target consumers and can establish a unique market position.

In the process of establishing this position, there needs to be a carrier that speaks for the brand, and packaging design, as the image representative of the brand, can make consumers identify with the brand’s value concept and product quality through visual channels.

After the positioning of the brand is clear, packaging design can be targeted and can serve the brand more effectively as a meaningful design.

Packaging design itself is a brand and culture-oriented discipline, which requires designers to carry out packaging design, not just to pursue the momentary benefits brought my creativity and fashion, but to make packaging design transform into an important way to establish brand connotation and create a lasting brand value through an accurate grasp of brand positioning.

The rules of series packaging

Cosmetics variety is unprecedented, consumers have a wider and wider choice.

As a company, it is necessary to classify and design product packaging through the efficacy and composition of the product to facilitate consumers’ identification and purchase of cosmetics.

The main purpose of product packaging classification design is to make a regular design by changing the printing color elements of the box packaging. Usually, the following combinations can be used for the packaging design of a series of products.

- The same container shape, different color printing offset box packaging color. This design can be implemented for cosmetic products with similar efficacy but different usage times.For example, the same series of morning cream and night cream, at this time more than the use of two-color printing offset box packaging color difference to distinguish the concept of time.

- The same container shape and container color. The same design style of box packaging, but the plastic box printing on one or several design elements to change the implementation of such design solutions are usually used for a series of cosmetics with the same function but different ingredients.For example, cosmetics that belong to the same fruit series use the same design style of box packaging because they all use fruit formulas, but the fruit formulas are divided into the pomegranate, lemon, tomato, and other formulas, so the plastic box packaging can be printed with the corresponding fruit pattern to distinguish them.

- The complementary shape of the container. The implementation of such design solutions are mostly products with matching functions.For example the same series of shampoo and conditioner, in order to reflect the unity of the two and imply that consumers should use them as a set to increase sales, usually the box packaging of the two will be designed as a whole, together with combined into a new overall shape.

Pictures

In short, adopting a corresponding design approach based on the different ways of classifying a series of cosmetics to provide consumers with a more effective, intuitive, and convenient way to guide their consumption will benefit both companies and consumers.

It should be noted that most cosmetic products packaged in boxes usually have different functional requirements for the front and the back.

The front is usually a reflection of the product’s logo image and design sense, showing the product’s own personality and style to interest consumers at first glance, while the back is usually just a large amount of explanatory text in a simpler form, as long as it is consistent in style with the front design pattern.

Conclusion

So, what’s the verdict? Is cosmetic packaging important to your success as a business?

The answer is undoubted yes. It’s not just about the product itself – the packaging also needs to be aesthetically pleasing and eye-catching if you want consumers to take notice.

And with so many products on the market these days, it takes more than a good product to make it stand out.

Different types of cosmetic packaging can help set your brand apart from the competition, so don’t neglect this aspect of your business.

If you’re looking for some advice on box packaging design or any other type of cosmetic packaging, feel free to contact us for more information. We’d be happy to help!

Everything You Want to know about Eco-Friendly Bag Packaging

Introduction

Since 6.1 2022, NSW Australia has banned the use of single-service plastic packaging. Actually, what happens in Australia NSW is not that hard to expect.

In recent years, the trend of eco-friendly packaging has become increasingly strong because of global warming.

A city like Seattle even ban the use of plastic straws and utensils in restaurants in June 2018.

There is no doubt that we will see similar laws targeting plastic packaging will sprout around the world.

Under such conditions, what packaging can we choose to replace the plastic packaging? We can not deny that plastic bags make a great convenience to your daily life. They are affordable and lightweight, which makes them proper in many circumstances.

Can we find alternatives to plastic packaging? The answer is yes.

In many areas, people already found the new packaging.

Through this blog, you will know the most popular kinds of Eco-Friendly Bag Packaging which serve as alternatives to plastic packaging.

Do not miss it!

The blog will include the following content

Plastic Pollution Around the World

Eco-friendly Bag packaging

PLA Bag

Non-woven Bag

Calico Bag

Plastic Pollution Around the World

The world produces about 300 million tons of plastic waste each year, of which more than 8 million tons enter the ocean, equivalent to dumping a garbage truck full of plastic into the ocean every minute.

In addition, the global annual use of plastic bags is about 1 trillion, and plastic bottles are about 200 billion.

Difficult to degrade plastic bags, and plastic bottles will exist in nature for hundreds of years.

Since 2000, the global consumption of plastic products has been equivalent to the sum of all years consumed before 2000, one-third of which ended up dumped in the natural environment.

In turn, plastic waste enters the human body through water sources.

A previous survey found that the global per capita intake of 1,796 plastic particles through drinking water, according to the weight of these plastic particles is about 5 grams, equivalent to the plastic used in a credit card, a year calculated about 250 grams, that is, 50 credit cards.

If this continues, sooner or later, the earth will not only be covered by plastic waste, but clean drinking water will also be less and less.

Therefore, many countries have taken action, some completely ban plastic bags, some are in the active research and development of alternatives, and some set up a long-term “plastic ban” goal.

Eco-friendly Bag packaging

PLA Bag

Packaging bags can be divided into biodegradable bags and non-biodegradable bags according to their degree of environmental protection.

Degradation can be divided into “degradable” and “full degradation”.

General biodegradable bags refers to the production process to add a certain amount of additives, such as starch, modified starch or other cellulose, photosensitizers, biodegradable agents, etc., so that their stability decreases, and then easier to degrade in the natural environment of plastic packaging bags.

Fully degradable bags are plastic products that are all degraded into water and carbon dioxide.

The main raw material of this fully degradable material is processed from corn, cassava, etc. into lactic acid, also known as PLA.

PLA material

PLA (polylactic acid) is a new type of degradable material that can be prepared by extracting starch from renewable plants, then making lactic acid through biological fermentation, and finally through chemical synthesis

PLA has excellent degradability and can be completely degraded by microorganisms in the end.

Products made from PLA can be completely degraded to CO2 and water after use, which is also non-toxic and non-irritating, That’s why

It is a widely recognized environmentally friendly material.

PLA has similar mechanical properties to polypropylene, while its gloss, clarity, and processability are similar to polystyrene, and its processing temperature is lower than that of polyolefin.

It can be processed into various packaging materials, fibers, and nonwovens through injection molding, extrusion, blistering, blow molding, spinning, and other general plastic processing methods, and is widely used in industrial, agricultural, medical, and civil fields.

The Pro and Con of PLA material

- Advantages

Biodegradable materials have their advantages in terms of performance, practicality, degradability, and safety.

In terms of performance, biodegradable plastics can reach or exceed the performance of traditional plastics in some specific fields;

In terms of practicality, biodegradable plastics have application performance and health performance similar to similar traditional plastics;

in terms of degradability, biodegradable plastics can complete degradation in the natural environment (specific microorganisms, temperature, humidity) relatively quickly after use and become fragments or non-toxic gases that can be easily used by the environment, reducing the impact on In terms of safety

The substances produced or left by the degradation process of degradable plastics are harmless to the environment and will not affect the survival of human beings and other organisms.

- Disadvantages

The biggest obstacle to replacing traditional plastics is the high production cost compared with similar traditional plastics or recycled plastics.

Therefore, biodegradable plastics have more substitution advantages in application areas such as packaging and agricultural films, which are short-lived, difficult to recycle and separate, and have low-performance requirements and high impurity content requirements.

Paper Bag

A Paper bag is a container made of paper, usually with an opening at the top for inserting objects.

Paper bags are commonly used for shopping, as they are inexpensive and disposable. Paper bags can also be recycled or reused.

Paper bags are made from a variety of paper types, including:

– Kraft paper: A type of paper made from wood pulp. Kraft paper is strong and durable, making it ideal for shopping bags.

– Recycled paper: Paper that has been used before and then recycled. Recycled paper is often used to make shopping bags.

– Laminated paper: Paper that has been coated with a thin layer of plastic. Laminated paper is more resistant to tearing and moisture than uncoated paper.

Paper bags come in a variety of sizes, depending on their intended use. Shopping bags typically range from small (10 x 15 cm) to large (60 x 80 cm). Gift bags and packaging bags can be even larger.

Paper bags can be decorated in a variety of ways, including:

– Printing: Paper bags can be printed with designs, logos, or text.

– Embossing: A design can be embossed onto the paper bag using a special plate.

– Debossing: A design can be debossed into the paper bag using a special plate.

– Foil stamping: A design can be stamped onto the paper bag using foil.

Paper bags can be made from recycled paper and are often recyclable themselves.

However, some types of paper bags, such as laminated paper bags, are not recyclable.

FSC Certification

As global forest problems became more and more serious: forest areas were decreasing, forest degradation was severe, and the area and quality of forest plants were declining,

some purchasers in Europe and the United States actively responded to environmental problems by proving that trees were legally sourced wood products, and finally the FSC Forest Certification was born to monitor the origin of wood products to ensure legality.

FSC( Forest Certification)’s mission is to promote environmentally friendly, socially beneficial, and economically viable forests worldwide through the development of recognized principles and standards for forest management.

FSC was founded in 1993 and its international center is now located in Bonn, Germany.

Non-woven Bag

Non-woven bags are a type of reusable bag made from polypropylene.

They are recyclable, durable, and lightweight, making them a great alternative to paper or plastic bags.

Non-woven bags can be used for shopping, storing items, or packing lunch. When choosing a nonwoven bag, look for one that is sturdy and has a reinforced bottom.

Avoid bags that have been treated with chemicals or dyes, as these can leach into food or clothing.

Non-woven bags are a great way to reduce your reliance on paper or plastic bags.

They are also an eco-friendly option that can help reduce waste and litter. When using a non-woven bag, be sure to wash it regularly to keep it clean and sanitary.

Avoid using it for raw meat or produce. Non-woven bags can last for years with proper care, making them a smart investment for the environment and your wallet.

We wrote a blog about the benefits of Non-woven bags, if you want to know more about the non-woven bags, read this blog:

https://primepac.com.au/benefits-of-non-woven-bag/

Calico Bag

Calico bags are reusable bags that are made from a natural fiber called calico.

Calico is a type of cotton that is often used for making quilts and other types of fabric crafts.

The bags are usually brightly colored and have a tight weave, which makes them ideal for carrying groceries or other items.

The term “calico bag” can also refer to a type of shopping bag that is made from recycled materials.

These bags are often found in stores that sell eco-friendly or sustainable products. They are also sometimes given away for free at events that promote green living.

Calico bags are a great way to reduce your reliance on disposable plastic bags. They can be used over and over again, which helps to save money and reduce waste.

Read this blog to get more information about Calico bags

https://primepac.com.au/calico-bag/

Why choose Primepac

At PrimePac, we bring together design experts and brand innovators to create fresh ideas, customized packages, and fully efficient processes.

We design creative packaging solutions that cater to a diverse global audience with the in-house knowledge and network of experienced professionals to meet the demands of every type of client.

From our dedicated sales team and warehouse staff in Australia to the experts at our production facilities in China, all of our employees are guided by four core values at the heart of our business: integrity, innovation, passion, and engagement.

Conclusion

So, what can you do to help? It might seem like a daunting task, but every small step counts.

If we all make an effort to reduce our reliance on disposable bags, we can start making a real difference in the amount of plastic pollution that ends up in our waterways and oceans.

And if you’re looking for some eco-friendly bag packaging options for your business, don’t hesitate to contact us.

We have a wide range of environmentally friendly packaging solutions that will suit your needs – and help keep our planet healthy and beautiful.

The Top 30 Cosmetic Packaging Suppliers In 2023

Introduction

Wholesale cosmetic packaging in Australia is a thriving industry that provides high-quality packaging solutions to cosmetic brands across the country.

From simple jars and bottles to intricate custom designs, wholesale cosmetic packaging companies in Australia offer a wide range of options to meet the specific needs of their customers.

If you are looking to source high-quality packaging supplies for your cosmetics business, look no further than the top 30 Cosmetic Packaging Suppliers listed below.

These companies are at the forefront of the cosmetic packaging industry, and they offer premium products and services that will help your business thrive.

We will also introduce other useful information about cosmetic packaging including factors to consider when choosing cosmetic packaging supplies, key elements of cosmetic packaging design,best cosmetic packaging design trends for 2024, and so on.

Whether you are just starting out in this industry or have been in the game for a while, this post is for you. We understand that the world of cosmetic packaging can be daunting, with its intricate designs, complex manufacturing processes, and ever-changing trends.That’s why we’ve put together this comprehensive guide to help you navigate through the challenges and make informed decisions for your cosmetic packaging needs.

So, let’s dive in and explore the world of cosmetic packaging together!

The blog will include the following content:

1.Top 30 Cosmetic Packaging Suppliers for Wholesale

2.The Different Container Types of Cosmetic Packaging

3.The Different Material Options for Your Cosmetics Packaging

4.Health & safety factors in cosmetic packaging

5.Environmental factors in cosmetic packaging

6.Shipping & logistics in cosmetic packaging

7.Factors to consider when choosing cosmetic packaging supplies

8.Benefits of cosmetic packaging wholesale

9.Four key elements of cosmetic packaging design

10.Forecasting 10 best cosmetic packaging designs for 2024

Weltrade Packaging

Weltrade Packaging Solutions is a company that provides innovative, high-quality plastic packaging to cosmetic brands and product manufacturers.

They are committed to delivering the best solution for our customers by going above any expectations they might have with their mission statement being “We’re honest,” which means telling it like you get it done without beating around the bush or sugar-coating anything;

Transparency also plays an important role when dealing directly with how much time/money will be needed before getting started because this allows both parties to know where each other stands from start till finish while having accountability towards one another at all times through regular checkups so there can never again.

Tel: +61 7 5597 0102

Address: Unit 1/8 Production Avenue, Molendinar Qld, 4214

Cosmetic Packaging Now!(CPN)

Cosmetic Packaging Now, LLC (CPN) is an industry leader in the supply of laboratory-grade cosmetic packaging containers.

Their range of containers is designed to meet all needs – from immediate use to custom-made and from functional requirements to aesthetic concerns.

From cosmetic airless bottles and jars to lip gloss containers and cosmetic bottles, they have scientifically superior products that all undergo extensive testing for quality assurance.

They pride themselves on providing the best Cosmetic Packaging solutions for consumers through CPN, so whatever your Cosmetic Packaging needs may be, Cosmetic Packaging Now is the top supplier!

Address: CENTRAL HEADQUARTERS 701 Commerce St. Dallas, Texas 75202

Customer Service: +1 (469) 833-2242

Sales: +1 (469) 263-1259

Email: info@cosmeticpackagingnow.com

My Skincare Manufacturer

My Skincare Manufacturer Pty Ltd is a company that specializes in manufacturing high-quality skincare packaging for both large brands and start-ups.

They have been operating since 2009, providing services to many famous companies all over the world including Kiehl’s Australia division where they are heavily invested in maintaining strict quality standards while remaining pure natural without any harmful chemicals or preservatives which make their products very effective at helping you take care of your skin correctly no matter what type it may be!

Address: 25 Craftsman Close, Beresfield, NSW, 2322 Australia

Email: info@myskincaremanufacturer.com.au

Tel : +61 2 4013 6032

Cosmopak

Since cosmopak Packaging Company began, they have been devoted to creating revolutionary products that bring ideas from conception all the way to launch and beyond.

Their experienced team has the know-how, intelligence, and creative vision to make it happen.

They specialize in eco-conscious packaging and high-performance formulas designed to move beauty brands forward – consistently producing groundbreaking results.

NY Phone: 516 767 9119

LA phone: 310 393 5511

CCS Packaging

CCS Packaging is an Australian-owned company that provides packaging and print services to industries such as Media, Consumer, and Personal Care for over 30 years.

The business has recently obtained HACCP certification which means they are committed not only to their work but also to customers’ needs by providing top tier service with excellent quality products at competitive prices on every project undertaken.

They’re FSC® certified! And they have also gained a new qualification -HACCP(food safety management system).

This means you can trust them when it comes down to getting your food graded packages checked or transported safely across borders.

Tel : + 61 2 9748 8333

Fax : + 61 2 9748 4966

Star Stuff Group

Their expertise in the packaging industry is unparalleled, with over 30 years of experience to back it up.

From pen technology and innovation all way through service delivery – the customers can rest assured that no detail goes overlooked when delivering quality products on time!

They focus on service innovation with an emphasis primarily placed on small-medium sized companies from Australia or New Zealand who need help delivering their products across borders in other countries such as South Africa USA UK et

Phone: 1300 885 044 or (07) 3488 8100

Fax: (07) 3821 4874

Email: sales@ssgp.com.au or fill out the contact form

Unit 1 / 14 Natasha Street, Capalaba QLD Australia 4157

HCP

HCP’s customer-centric approach to cosmetic packaging design and manufacture has made them a global leader in the industry.

They offer tubes for all types of color cosmetics including nail polish bottles, as well as skincare products such as eyeshadow palette cases or lip gloss displays that meet international safety standards set by regulators across various markets they serve with high-quality product offerings always exceeding expectations

Address: HCP Packaging USA, Inc. 430 Mountain Avenue, Suite 402,New Providence, NJ 07974, USA

Tel : +1 908 643 7720

Certina Packaging

Whether you’re looking for a premium product box or something that’s more industrial, Certina has the solution to fit your needs.

With their vast array of decoration technologies, they can create exactly what you need. There is no limit on how unique and special these boxes will be made to last as long as possible while also being eco-friendly too!.

Address: PARC INDUSTRIEL OUEST, VEYZIAT, 01100 OYONNAX, FRANCE

Tel: +33 4 74 73 16 16

Faca Packaging

Faca Packaging, a world leader in the design and production of high-end cosmetic packaging for over 50 years.

They use their experience to create exclusive brands with innovative products that are sold worldwide through dealerships or online retailers such as Amazon Prime.

Faca’s success can be attributed largely due to the company’s continued investments into R&D; they have 300 active patents waiting on patent lawsuits from other companies which means Faca will likely continue seeing growth even when others may struggle because innovation matters most!

With an all-European factory 100% located within clean rooms where standards like ISO 9001:2015 strictly apply, this gives clients peace in knowing what quality standards must meet if there were any concerns about product delivery.

Email:: packagingfaca@facasa.com

Address: Ctra. del Mig, 1-13, 08940 Cornellá de Llobregat, Barcelona

Phone: :+34 93 377 98 12

Fax: +34 93 377 32 11

Quadpack

Quadpack is a global leader in cosmetic packaging manufacturing with production facilities around the world, including Europe and North America as well as the Asia Pacific.

The company’s founders have over 35 years of combined experience developing innovative products for some of today’s best-known brands like L’Oréal Paris or Estée Lauder cosmetics – which means they know how important it can be to produce safely without compromising quality.

Address: 2840 Commodore Dr.Suite 120, Carrollton, TX 75007

Tel: 1 (877) 239-2831

APC Packaging

APC Packaging is quickly becoming the preferred partner for many brands when it comes to achieving perfect packaging.

APC specializes in providing comprehensive assistance throughout the whole process, from pricing to engineering and production turnaround times.

APC also provides customers with innovative, sustainable solutions at competitive prices, enabling rapid response times and customer satisfaction along with APC’s years of expertise and know-how.

Address: 1850 West McNab Road,Fort Lauderdale, FL 33309

Tel: 954-978-4567

Email: info@apcpackaging.com

ICS

International Cosmetic Suppliers Ltd., established in 1991 by founder and CEO Sue Nichols. ICS provides masstige brands with international support through offices located around the world including Asia (Mainland), North America(United States), and Australasia.

The company’s growth over time has led to the expansion of new development teams and the addition of extensive quality assurance staff for each region. This expansion helps ensure high standards are met on every project they undertake. Additionally, the company employs marketing professionals who provide clients with unmatched guidance in making decisions about their needs within beauty supply chains.

Tel: +86(0755)82396393

Address: Unit 12H Noble Centre,1006 Fuzhong 3rd Road, Futian District, Shenzhen 518038

EXPO PACK

The beauty of nature can be found in everything EXPO do, from the packaging to how it looks.

EXPO PACK has been designing and manufacturing products for over 30 years, emphasizing the power of storytelling while ensuring customer satisfaction through high-quality materials that offer easy customization options and environmental friendliness. This commitment is supported by beautiful design features, such as heavy-duty bottles made from PET, a type of petrochemical plastic.

In addition, EXPO offer custom-made solutions so you don’t need to worry about your needs going unfulfilled.

Address:No. 3, Ziqiang 1st Rd.Zhongli Dist, Taoyuan City 32063, TAIWAN

Tel: 886-3-4631598

Fax: 886-3-4631511

Email: info@epopack.com

SeaCliff Beauty

SeaCliff Beauty is passionate about packaging for the beauty industry.

They are committed to creating long-lasting relationships with their customers by providing top-notch customer service that meets all of the customers’ needs and exceeds expectations every time!

SeaCliff offers high-quality, professional-grade products in both custom-designed box retail packages as well as turnkey solutions which means you can get back up on track quickly whether it be marketing or technical support.

Address:9840 Irvine Center Drive,Irvine, CA 92618

Tel: (949) 955-1239

Email:sales@seacliffbeauty.com

APG Packaging

APG Packaging is a veteran-owned business that has been providing high-quality products at affordable prices for over 25 years.

They have factories in both the US and Asia to ensure fast production speeds while maintaining below-market rates cost structures–making them your perfect partner.

Their staff are dedicated professionals with extensive experience managing large projects across various industries; they take pride not only in meeting deadlines but also in exceeding them.

Address: 1350 Mountain View Circle,Azusa CA

Open Hours: Monday to Friday: 8:00AM – 5:00PM

Contact: (626) 385-5858

Email: Hannahp@apackaginggroup.com

SKS Bottle and Packaging

The founder of SKS Bottle and Packaging, Inc had the vision to help people live healthier lives by providing them with environmentally friendly products.

With this goal in mind, they created eco-friendly bottles that are both affordable for all budgets as well made from 100% recycled materials which will never end up in your local landfill or incinerator because it’s too small.

Since its inception 35 years ago (1986) SKS has grown into an industry leader not only among packaged goods but also within healthcare facilities where many hospitals order their packaging supplies regularly – including some Fortune 500 companies.

Address:10 Skyward Dr. Saratoga Springs, NY 12866

Phone: 518-880-6980

Fax: 518-880-6990

Paper Mart

Paper Mart has grown from a small, Los Angeles garage to a catalog company to becoming the largest discount packaging supply company in the United States. For over 100 years, they’ve watched their family grow to 250+ employees and provide countless people with packaging, craft, and party supplies.

Paper Mart has gained popularity for quality products, diverse inventory, and efficient customer service. They often cater to both individual customers and businesses looking for cost-effective packaging solutions.

Address: 2164 N. Batavia Street Orange, CA 92865

Tel: 800.745.8800

Email:info@papermart.com

Lumson

Lumson, the company in Capergnanica (Cr) and S. Maria di Sala that produces 120 million plastic bottles per year with an investment over 3 shifts of 250 employees working for them.

Lumson is one out of three factories investing in new technology which can produce different kinds of technologies making it very industrial-strength when manufacturing packaging materials.

However, Lumsoin’s most important asset isn’t only its equipment but also its workforce who have skilled hands thanks to education programs provided throughout all levels.

Address:: Via Tesino 62/64 – 26010 – Capergnanica (CR) Italy

Tel: +39 0373 23 31

Fax: +39 0373 23 33 55

Petro Packaging

Petro Packaging Company Inc. has been providing customers in northern New Jersey with cutting-edge extrusion solutions for more than forty years.

This third-generation, family-owned and operated business was one of the first to pioneer the use of CAB, CAP, and PETG materials in their extrusion processes during the 1960s.

Petro Packaging is now well known throughout the plastics industry for its comprehensive selection of extrusions that can be used for virtually any application.

With their extensive experience processing thermoplastic materials, Petro Packaging Company Inc.’s commitment to excellence has been established as one of the premier plastic tube and profile extrusion houses around today.

Address:: 16 Quine St., Cranford, NJ 07016

Tel: 908.272.4054

Fax: 908.272.2836

Email: Info@Petropackaging.Com

Bianco Skincare

Small and medium skin care product companies and beauty shops often have unique needs when it comes to packaging their goods.

Bianco Skincare Packaging offers them a solution. They provide high-quality Cosmetic and Skincare Packaging with small minimum orders, with MOQ 500pcs for regular packaging, or 1,000pcs for Printing Packaging.

This allows these businesses to achieve their desired visuals with the utmost reliability of Cosmetic packaging manufacturers.

With Biancos’s turnkey solutions, these companies have found the right partner to succeed in an extremely competitive market.

Address:: Room341-Build 3,8 Guangming Rd, Dongcheng District, Dongguan City, Guangdong Province China

Tel:+61 03 9887 7339

Email: contact@biancoau.com.cn

The Cosmetics Boxes

The Cosmetic Boxes offers proficient packaging services for over a decade to the cosmetics industry on behalf of their veteran management and skillful outcome of products.

They offer cost-efficient packaging solutions to all businesses and platforms ranging from personal business to colossal scale business.

The state-of-the-art printing mechanism and advanced technology enable them to provide wholesale cosmetics packaging such as hair color packaging, eye shadow boxes, lipstick boxes, moisturizer packaging, essential oil boxes, fragrance boxes, etc.

The Cosmetic Boxes also offers premium quality printing services for custom-printed boxes Australia-wide to transform your product packaging with customized packaging solutions.

Address: 903/50 Clarence St, Sydney NSW 2000, Australia

Tel: +61290988368

Website: https://www.thecosmeticboxes.com.au/

Buy Cosmetics Boxes

Buy Cosmetic Boxes has been a part of Printing & Packaging Limited, a leading online printer, marketing, and technology company in Australia since 2005.

They help small businesses grow by undertaking various on-demand business printing and graphic print orders online. They use a high-quality printing press and easy-to-use online ordering for customers at discount printing costs.

Some of their worth mentioning products in cosmetics packaging include hair care packaging boxes, personalized lipstick boxes, custom lip glosses boxes, branded cream boxes, essential oil boxes, cosmetics bags, etc.

Address:Unit 1, 14-16 Gordon StreetBankstown, NSW, 2200

Tel:(02)-9158-8455

Website:https://www.buycosmeticboxes.com.au/

Sismic Australia

Sismic Australia has been one of the premier distributors to spas, beauty salons, skincare, cosmetic, and pharmaceutical industries since its foundation in 2004.

They supply raw materials and finished products to the beauty salons, skincare/spas, cosmetics, and pharmaceutical industries.

They also offer top-class Private Label services to evolving businesses, large established brands, beauty salons, spas, and other skincare professionals.

Their integrated service from the ideation to the packaging includes the custom manufacturing & development, filling, labeling, and shipment of the products, facilitated with company guidelines.

Address:Sismic Australia Suite 2.12 203-205 Blackburn Rd Mt. Waverley 3149 Victoria Australia

Tel:+61-3-9887-8888

Website:http://sismic.com.au/

Emenac Packaging

Emenac Packaging delivers unparalleled customized printing and packaging solutions as they address the packaging needs of unlimited businesses in Australia UK, Canada, the USA, and worldwide.

Emenac Packaging assists many businesses in their packaging needs and offers cost-effective packaging solutions, facilitated with their in-house press in Australia along with offshore printing facilities in Asia and Africa.

Their premium printing services, free shipping, unique customized designing, and fastest turnaround win them global customers. They have categorized cosmetic boxes according to shapes, style, and material for packaging products.

Address:Level 10, 555 Lonsdale Street, Melbourne, Victoria, VIC 3000, Australia

Tel:+03-9088-3189

Website:https://www.emenacpackaging.com.au/

White Label Cosmetics & Packaging

White Label Cosmetics & Packaging started with an aim to fill a gap in the market of high-quality cosmetics & packaging products purchased at the lowest possible prices.

Their services of cutting-edge and effective skincare formulas integrated with a wide array of packaging and custom printing solutions, offer customers an opportunity to produce their very own skincare line or expand the pre-existing brand.

The wholesale cosmetics packaging products include boxes, unique bottles (droppers/glass/acrylic bottles), bags, plastic/PET jars, bamboo jars, and private labeling skin care services.

Address:22-30 Wallace Ave, Derrimut VIC 3030, Australia

Tel:+61-3-9103-1412

Website:https://whitelabelcosmeticsandpackaging.com.au/

Synergy Packaging

Synergy Packaging is the leading supplier of 100% Australian-made plastic packaging.

It has been a specialized manufacturer and supplier of quality packaging solutions to a wide range of industries such as cosmetics, personal care, foods/beverages, and the pharmaceutics sector.

They also produce PET bottles and jars by recycling containers after collecting, sorting, and re-granulating them into plastic pellets.

Address:10 International Square, Tullamarine VIC 3043, Australia

Tel:+61-3-9338-2626

Website:https://www.synergypack.com.au/

Primepac

Here at PrimePac, we bring together design experts and brand innovators to create fresh ideas, customized packages, and fully efficient processes.

We design creative packaging solutions that cater to a diverse global audience with the in-house knowledge and network of experienced professionals to meet the demands of every type of client.

From our dedicated sales team and warehouse staff in Australia to the experts at our production facilities in China, all of our employees are guided by four core values at the heart of our business: integrity, innovation, passion, and engagement.

Address:15/10 Chilvers Rd.Thornleigh,NSW 2120

Email:info@primepac.com.au

Tel:(02)9008 1338 (02)9008 1394

The Different Container Types of Cosmetic Packaging

Understanding the diversity of suppliers and their unique offerings paves the way for crafting impeccable brand experiences. Yet, it’s equally crucial to understand the intricate details of container types and material choices. By researching these facets, brands can build not just an alluring visual identity but also ensure practicality and sustainability in their product presentation.

When it comes to cosmetic packaging, there are three primary container types: jars, bottles, and tubes. Each type of container has distinct advantages and benefits for storing and delivering certain cosmetics products, and understanding the differences between them is important for choosing the right packaging for your product.

Jars

When it comes to cosmetics packaging, jars are among the most popular choices due to their versatility and range of sizes. Jars are especially useful for products that may not pour well. Common products that are packaged in jars include powders and thicker products like face creams, skincare lotions, and hair gels. Jars are typically made from glass, plastic, or other skincare packaging materials, depending on the needs of the product. In terms of cosmetic packaging type, jars are a great option due to their airtight seal, which helps keep products safe and fresh. Jars are also an aesthetically pleasing option for packaging, as they come in a variety of shapes, sizes, and colors. Overall, jars are an ideal choice for cosmetic packaging due to their versatility, durability, and variety.

Bottles

For cosmetic packaging, bottles offer a range of options that can be tailored to the needs of the product. From glass bottles for lotions and liquids to plastic bottles for shampoos and soaps, the skincare packaging type and cosmetic packaging type you need can be found. Different shapes and sizes are available to suit the product and the style of dispensing desired, such as pumps, sprayers, and droppers. Different colors and materials can also be used for a unique look. Additionally, labels can be added to enhance the look and provide valuable information, such as product ingredients and instructions. In summary, bottles are a great way to package and display your product, allowing you to create a professional and attractive aesthetic for your customers.

Tubes

Tubes are also a great option for cosmetic packaging that can be tailored to the needs of the product, providing a range of possibilities. Ointments, liquid makeups, and other products with a wide variety of viscosities can be stored in squeezable tubes. This allows the user to dispense the product with more control, depending on the desired amount. Tubes also provide a more hands-on experience for the consumer, which is great for products like facial care. The tube size and shape can also be customized to fit the product, making it easier to store and transport. Additionally, tubes also have a longer shelf life than other packaging, as they protect the product from sunlight and air exposure. Tubes are a great choice for many cosmetic products and provide a unique and effective packaging solution.

The Different Material Options for Your Cosmetics Packaging

When it comes to cosmetic packaging materials, there are a few different options. These materials include glass, plastic, and metal, each of which has its own unique advantages and disadvantages. In order to choose the best packaging option for your product, it is important to understand the characteristics of each material.

Glass

Many different types of glass are available for cosmetic packaging needs. It is an excellent choice for products that need to be seen clearly, such as smaller bottles for essential oils or jars for cosmetics. While glass packaging can be costlier than other materials, buying in bulk can help reduce costs. Glass is also a very durable material and can be designed in many shapes and sizes. It is also recyclable, making it an environmentally-friendly choice. Moreover, glass is resistant to water, air, and chemicals, providing an extra layer of protection to delicate products. However, it can be heavier and more fragile than other materials, so you need to be careful when handling it. Overall, glass is a great option for cosmetic packaging and can provide both practical and aesthetic benefits.

Plastic

When looking for the perfect packaging for your cosmetics, there are many different types of plastic to choose from. These plastics include Low-Density Polyethylene (LDPE), Polyethylene Terephthalate (PET) and High-Density Polyethylene (HDPE). Each material has its own unique characteristics and benefits that should be taken into account when selecting the right packaging.

LDPE:

Among the different materials available for creating cosmetics packaging products, LDPE stands out for its flexibility. It is a great option for tubes and squeeze bottles, providing a bit more give than other plastics. LDPE is also lightweight and relatively inexpensive, making it a popular choice for many products. It is also a recyclable material, allowing for greater sustainability in cosmetics packaging. LDPE is also very durable, making it a great option for products that need to withstand wear and tear.

PET:

PET plastic is a popular choice for cosmetic packaging due to its strength, transparency, and cost-effectiveness. Its rigidity and clarity make it ideal for cosmetic spray bottles and jars that need to showcase makeup or other products. It is also lightweight, shatterproof, and provides a good barrier to protect the product from external elements. It is an economical option that offers a good balance of cost, quality, and performance.

HDPE:

Drawing from the benefits of PET plastic, HDPE offers a different option for cosmetic packaging due to its superior strength and cost-effectiveness. Its natural color prevents transparency, but it’s also more resistant to moisture and cracking. HDPE is lightweight and easy to transport, making it ideal for large-scale orders. In addition, it’s recyclable and can have a longer shelf life than PET. As such, it’s a great choice for businesses looking to save on packaging costs while still providing quality products.

Metal

Metal can offer an array of attractive features to consider when selecting the right material for your cosmetics packaging. Aluminum is lightweight, easy to handle, and has a sleek, elegant look. It’s also highly durable and non-toxic, able to withstand tough transport and storage conditions. Plus, it’s recyclable and can easily be melted and reused. Plastic and glass may be better suited for products where visibility is important. Aluminum bottles are great for dry or powdered products, sprays, and deodorants, while canisters are ideal for scrubs, creams, candles, salves, butter, and lip or body balms. Metal can be a cost-effective option, with unique benefits for small business owners.

Health & safety factors in cosmetic packaging

The health and safety of consumers should always be a priority when considering cosmetic packaging, as any misuse or mishandling can lead to serious consequences. It is essential that the chosen vessel is able to protect the contents from contaminants, sunlight, and other sources of degradation. Moreover, deceptive labeling or marketing claims, inaccurate ingredient lists, and the exclusion of expiry dates or safety warnings can all directly impact the safety of consumers and should be carefully considered. Additionally, avoiding known toxic or harmful chemicals is important due to increased consumer awareness and education. BPA-free containers are thus recommended to ensure a safe and healthy product.

Environmental factors in cosmetic packaging

Environmentally-friendly packaging is increasingly becoming a priority for cosmetic brands as they strive to reduce their impact on the environment. Reusing, recycling, and biodegradable materials are preferred over those that are not. Minimalistic packaging that is attractive and rustic is on-trend and can help promote positive consumer perception. Glass and aluminum are highly recyclable, and PET plastic is often seen as a more eco-friendly choice. Reducing packaging wastage and maximizing the product-to-package ratio can help minimize resource usage. Brands that embrace sustainability can be more attractive to eco-conscious consumers and help protect our ecosystems.

Shipping & logistics in cosmetic packaging

Ensuring safe product delivery starts with smart packaging choices. Consider your product’s size, material, and vulnerability during transit. Fragile glass items need layers of protection; aluminum products, sturdy cushioning. Liquids require waterproof wrapping, while crushable items need secure padding. Test deliveries preemptively to anticipate issues. Finally, elevate the unboxing experience with appealing outer packaging—colors, ribbons, and personal touches make a lasting impression. Thoughtful packaging ensures products arrive intact, delighting customers and avoiding costly mishaps.

Factors to consider when choosing cosmetic packaging supplies

Now that you have learned the different container types and material options for cosmetic packaging , now it’s time to know what are the factors to consider when choosing cosmetic packaging supplies. There are several factors to consider in order to ensure that you are selecting the most suitable product for your needs.

Define Your Ideal Buyers

Before deciding on which cosmetic packaging supplies to use, it is important to consider who your ideal buyers are. Knowing the demographic and psychographic characteristics of your target audience will not only help you create packaging that resonates with them, but also provide insight into the type of packaging that will be most suitable for them. Consider the problem that your products solve, the age group, gender, and lifestyle of your target audience, as well as their interests, values, and beliefs. By understanding these factors, you can create packaging that is tailored to your ideal buyers, making it more attractive to them.

Establish a Brand Positioning